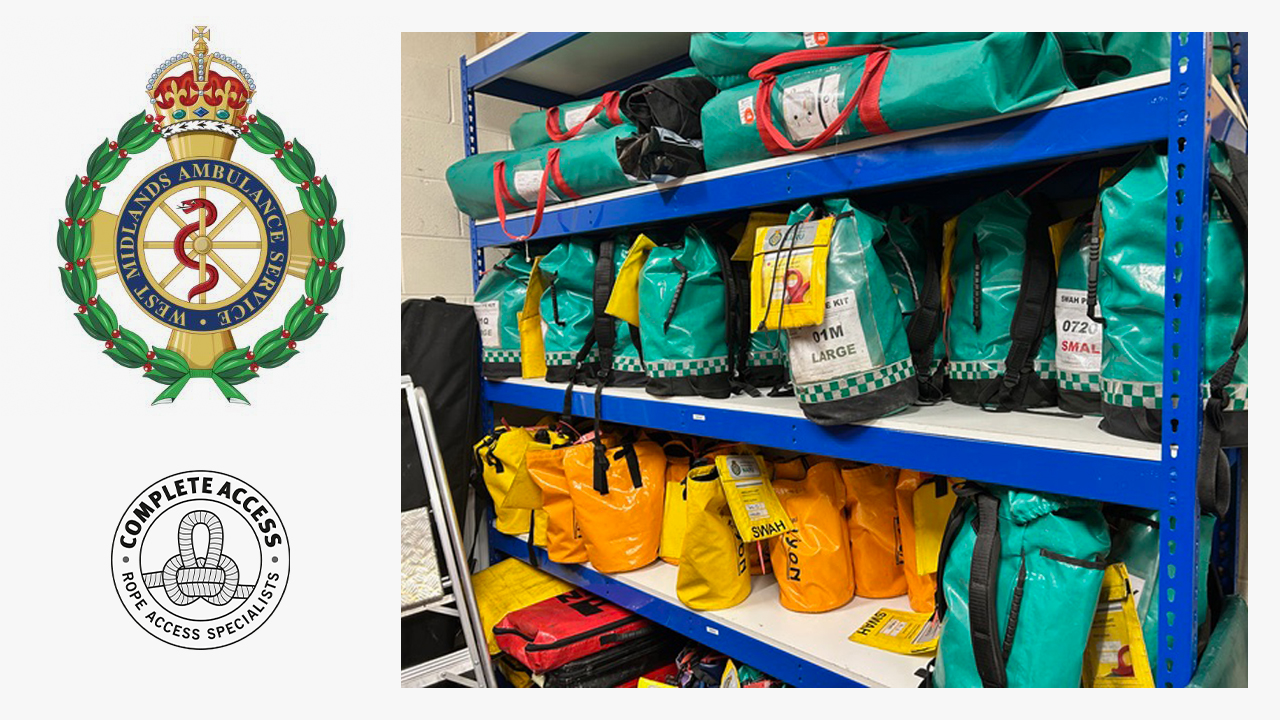

We are proud to have been asked to undertake 6 monthly LOLER PPE Inspections for West Midlands Ambulance Service Hazardous Area Response Team WMAS HART for 40 of their Rescue Kits.

As one of the primary Rope Access Companies to have been formed in the West Midlands back in 2000, we were the obvious choice to undertake such an important task.

Our PPE Inspectors carried out the visual and tactile inspections to the rescue kits using our knowledge of current equipment and how to spot what is a Pass or Fail or To Monitor.

Personal Protective Equipment (PPE) inspections are visual and tactile examinations of safety equipment to ensure it’s fit for purpose and compliant.

Why inspect PPE?

- To ensure PPE is in date and effective.

- To extend the life of safety equipment.

- To identify when PPE has passed its useful life and needs to be disposed of

- To ensure PPE is compliant with regulations.

How often to inspect PPE?

- Before each use – Pre Use checks are imperative.

- At regular intervals throughout the working day.

- More frequently for high-risk workplaces or environments.

- After any incident or exposure to hazardous substances.

Who should inspect PPE?

- A competent person with the relevant knowledge and experience

- A person who is financially and legally independent.

What to check for…

- Cuts, cracks, tears, abrasion, and scorch marks

- Broken stitches, loose or worn threads

- Signs of damage, distortion, or corrosion

- Correct operation of buckles

- Serious reduction in width or thickness of the webbing

- Serious distortion to the weave pattern.

Inspection checklist books or software to examine your safety equipment can be used dependant on your operational requirements, in this case, for WMAS HART everything was hand written.